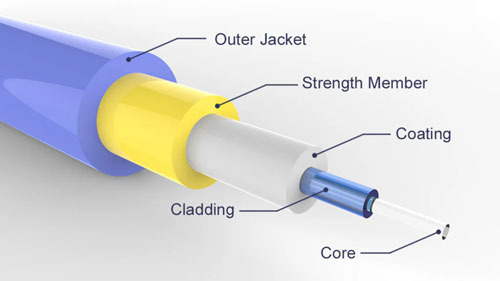

The fiber is fragile and easy to break, the cable jacket is a good measure to protect the fiber been damaged. The cable structure includes buffers, strength members, and jackets. The following articles offer a brief introduction to the cable jacket used inside the data center.

LSZH

LSZH (low-smoke, zero halogen) jacket is free of halogenated materials which can be transformed into toxic and corrosive matter during combustion. LSZH is a good cable jacket choice for enclosed installations.

PVC

PVC (Polyvinylchloride) is usually low-cost, flexible, and fairly rugged. It can be formulated to function in a variety of environments and applications. It is used as a cable jacket material for both indoor and outdoor cables.

PVDF

A PVDF (Polyvinylidene Fluoride) coating does not react with most solvents and chemicals. It offers excellent resistance to abrasions and wear, high dielectric strength, is resistant to weathering, and can extinguish itself in the case of a fire. They also do not produce much smoke if there is a fire. This coating is a good choice for indoor plenum cables.

TPU

TPU (Polyurethane) jacket featured with high abrasion resistance, low-temperature performance, high shear strength, high elasticity, transparency, and oil and grease resistance. Used in industrial-grade cables.

HFFR

HFFR TPU (Halogen-free Flame Retardant Polyurethane Thermoplastic Polyurethane) compositions are replacing halogen-containing, flame-retardant TPU compositions in several applications including, but not limited to, the insulation and protective jackets for the wire and cable associated with personal electronic devices and cables deployed in enclosed spaces. These HFFR TPU compositions can provide excellent flame-retardant performance and mechanical properties including excellent flexibility.

Hytrel® TPE

Thermoplastic polyester elastomers (TPE) provide the flexibility of rubbers and the strength of plastics. The material offers excellent flex fatigue and broad use temperature. It resists tearing, flex-cut growth, creep, and abrasion, showing outstanding toughness while resisting hydrocarbons and many other fluids.

PE

PE (Polyethylene) has excellent properties of moisture and weather resistance and has good electrical properties over a wide temperature range. It’s also abrasion-resistant. Typically used as a jacket material for Outside Plant fiber optic cables.