High power fiber cables are primarily applied in industrial applications and are used for transferring the laser beam from the source to the application even at distances of several meters. The flexible connections find their application especially in the areas of materials processing like laser welding, cutti ng and drilling. For the laser fibers to operate reliably in harsh industrial environments, they require a certain robustness. Nevertheless, the fiber must be as free of stress and distortion as possible, but also stably mechanically fixed, provide tensile strength and, respectively, tear-resistance so that the optical properties are ensured.

ng and drilling. For the laser fibers to operate reliably in harsh industrial environments, they require a certain robustness. Nevertheless, the fiber must be as free of stress and distortion as possible, but also stably mechanically fixed, provide tensile strength and, respectively, tear-resistance so that the optical properties are ensured.

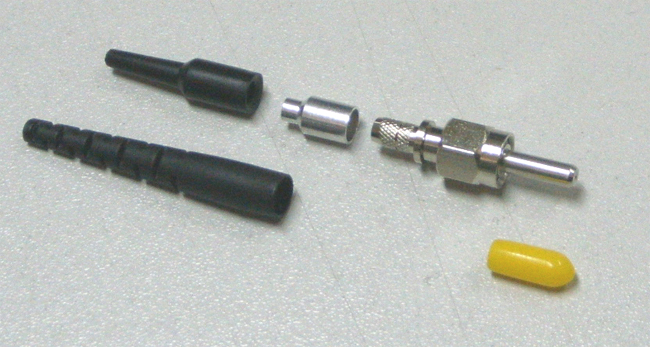

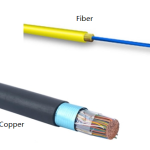

The potential performance depends on many factors, above all, on the fiber’s core diameter, the beam profile of the laser and, moreover, the spot size of the focused laser beam as well as its central alignment to the fiber core. Ideally, the spot diameter should account for about 80% of the fiber core. In addition, a plug must absorb and release the heat formed inside the fiber core. In this case, the plug ferrule consists of copper alloys with good thermal conducting properties, for higher power, cooling is necessary. At power levels up to 50 watts, usually no heat sink is necessary, provided the cladding modes are not stripped off. Otherwise, it is recommended to use an appropriately sized heatsink at just 20 watts, assuming that 1% of the power already is guided in the cladding. For this reason, Tarluz employs its very own developments which are based on SMA and D80 standards. The cable design is drafted individually according to the application requirements. The assembly comes in various alternatives of fiber, connectors and protective tubes.

Main Features:

- Single- and multimode fibers

- Wavelength range: 190nm to 2300nm

- Fiber core diameter: 100µm to 2000µm

- Numerical Aperture: 0.10 to 0.49

- Temperature range of -40°C to 350°C

- Connector types: HP-SMA, D-80, copper ferrule

- Ferrule area epoxy free

- Thermal management: active and passive cooling

- Length defined mode stripping

- End cap to reduce the power density

- Fiber Monitoring